WRITTEN BY: KAITLIN CASTOR

Circular VS Linear Supply Chains

A Deep Dive into Supply Chains

A report from Kaitlin Castor, current Master of Environmental Science and Management Student at UCSB.

What is a Circular Economy?

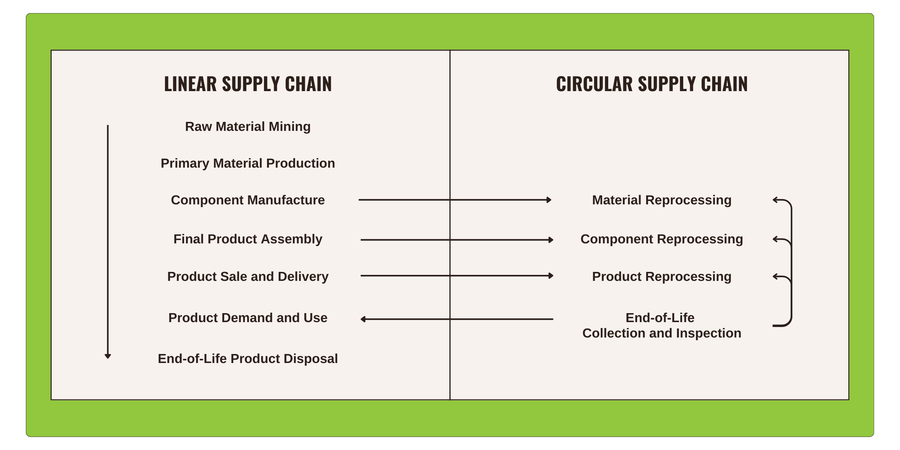

The Circular Economy is a term you may have heard of in the modern environmental movement, but what does it even mean? In short, the circular economy is a fresh new name for reduce, reuse, and recycle, also known as a supply loop. A supply loop challenges linear supply chains – the status quo – for a more sustainable, climate-friendly flow of goods and materials by reprocessing products into secondary resources. Let’s dive deeper into an overview of the circular economy.

Supply Chains 101

A supply chain refers to the sequence of creating a product, from extracting raw materials to product sale. The life cycle of a product ends with end-of-life product disposal, however many supply chain managers and corporate leads pay no attention to this aspect.

Linear supply chains have been standard since the industrial revolution, and this linear flow of materials ends when products enter the landfill. As research has shown, mining raw, finite materials is an energy-intensive, disruptive process. And what happens to this material? It lives a usually short and wasteful lifecycle. We witness this decrease in product use in real time – for example, the switch from fast fashion to ultra fast fashion. As consumerism continues to increase, our landfills pile higher, and the climate crisis continues to exacerbate, circular supply chains are an applicable solution to extend the life of materials.

Circular Supply Chains keep materials out of the landfill by circulating them back into various stages of the supply chain. Circulating end-of-life products diverts materials from the landfill and prevents the extraction of raw materials from the earth. Instead of sending old clothes to the landfill, what if we could reprocess them back into yarn to make new clothes? By utilizing secondary resources through reuse – collecting, recycling, and reprocessing – to give materials another life, supply loops reduce waste and energy use.

Environmental Benefits of Supply Loops

The potential environmental benefits of a circular economy are exponential, however it is rarely straight forward. By quantifying material flow, we start to understand just how powerful of an environmental impact the circular economy can be. This is determined by the amount of avoided primary production and the difference in the environmental impact between producing new material and repurposing used material. For example, harvesting, processing, and spinning cotton thread versus breaking down an article of clothing, separating by fiber type, and respinning for cotton yarn. Research supports reprocessing often requires significantly less energy compared to primary production, but it is important to note different supply loops will have varying environmental impacts.

Aluminum recycling is a great success story that illustrates environmental savings. Aluminum scrap collection and recycling is 0.5kg CO2 eq / kg secondary ingot, significantly less than primary aluminum production (9kg CO2 eq / kg primary ingot). Similarly, aluminum in the landfill is 0.5kg CO2 eq / kg of scrap. This puts into perspective the importance of avoiding primary production versus avoiding the landfill. Afterall, all products and materials will require eventual disposal – the only products that require no disposal are the ones we never make. It may be true no product can be used forever, but we can significantly delay and decrease disposal and curb carbon emissions through the circular economy.

Challenges of Supply Loops

Although the circular economy seems like a no-brainer (why wouldn’t we extend the life of materials?), implementation of supply loops faces challenges. End-of-life products need to be collected and pre-processed before getting reprocessed into a secondary output. The big three challenges include limited collection of end-of-life products, feasibility of reprocessing, and market demand for a reprocessed secondary resource. It is challenging to competitively match supply with demand in a system built off of linear supply chains and the extent reuse can displace primary production is questionable since reuse products are seldom perfect substitutes. One supply loop does not fit all and there are different types of supply loops to consider: closed vs open loops, single vs multi loops. In addition, the circular economy must displace primary production, otherwise there is only market growth and no environmental savings.

Reuse and recycling will not automatically displace primary production and a successful circular economy requires system change. In order to adopt a circular economy, industry and policy must support new technologies, infrastructure and a just transition. This learning curve will knock down feasibility and expense barriers that linear supply chains once faced. We see this shift and success with the introduction of more EPR policies targeting specific products. In the United States, there are over 146 EPR policies across 35 states representing 21 product categories, including the Responsible Textile Recovery Act of 2024 in California.

What’s Next and How You can Help

Supply loops require industry change, but products are governed by consumer behavior. Through purchasing power and utilizing proper waste streams, you can support the development of the circular economy. Apparel and textiles are a great example and can avoid the landfill through thrift stores or initiatives like Retold Recycling! Other products with different waste streams for reuse include electronics, batteries, paint, mattresses, pharmaceuticals, and carpet. Lastly, staying educated is one of our most powerful tools as individuals, so thank you for reading this and staying informed.